Work Management

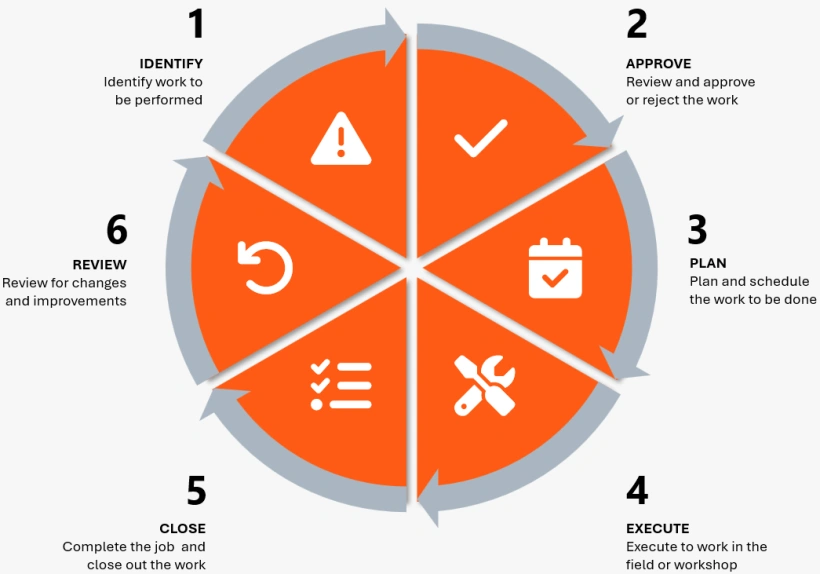

Maintenance work management in Samurai follows a recognised maintenance industry process that takes work from initial identification through to completion and review. The core of this process is the work order. Every activity, from small repairs to major planned maintenance, is managed and tracked through a work order record. This ensures that work is visible, prioritised, scheduled and completed in a consistent and auditable way.

The stages form a continuous cycle of planning, execution and improvement. This helps maintenance teams keep control of backlog, improve work quality and ensure that resources are used effectively.

Work Management Steps

The diagram represents the work management process as a repeating cycle. The steps below align directly with the diagram.

| Step | Title | Detailed Description |

|---|---|---|

| 1 | Identify work to be performed | Work is identified by operators, inspectors, maintainers or automated triggers. This may be a fault, inspection finding, hazard, improvement opportunity or planned maintenance requirement. In Samurai, this is captured as a Work Request or by creating a Work Order directly when appropriate. |

| 2 | Review and approve or reject the work | Supervisors or planners review the request to validate the issue, set priority and determine if the work should proceed. Approved requests are converted to work orders. Rejected requests are closed with a reason. This stage controls backlog growth and ensures only necessary work enters the system. |

| 3 | Plan and schedule the work to be done | Work orders are planned so they can be executed safely and efficiently. Planning may include adding parts, labour estimates, documents, job instructions, risk controls and assigning work to an event (for advanced assets) or adding a scheduled date (for standard and basic assets). This prepares work for execution and ensures resources will be available. |

| 4 | Execute the work in the field or workshop | The work is carried out by technicians. The work order is set to In Progress and technicians record the actual work performed, time spent, parts used and any issues discovered. Photos, notes and follow up work may be added. |

| 5 | Complete the job and close out the work | After the job is finished, the technician or supervisor records completion details and sets the work order to Complete. Completion details may include actual start and finish times, failure codes for breakdowns, completion notes and any attachments. This creates an accurate maintenance history. |

| 6 | Review for changes and improvements | Completed work is reviewed to support continuous improvement. Supervisors, engineers and planners assess recurring issues, analyse downtime, monitor backlog trends and refine maintenance strategies. This step ensures lessons learned result in improved planning and work practices. |

Summary

The Samurai work management process mirrors the industry standard maintenance cycle. It ensures that work is:

- Correctly identified

- Reviewed and approved

- Properly planned and prepared

- Executed safely and efficiently

- Completed and recorded

- Reviewed for improvement

This cycle underpins effective maintenance management, supports compliance and builds a reliable history for better asset decision making.